Going Granular: Why We’re Stripping a Drill Rig Down to the Last Bolt

What does it take to truly know a piece of machinery? At our core, we believe it’s about understanding it from the inside out. That’s why we’ve embarked on a massive project: taking a complete SAR100 drilling rig and systematically stripping it down to every last component.

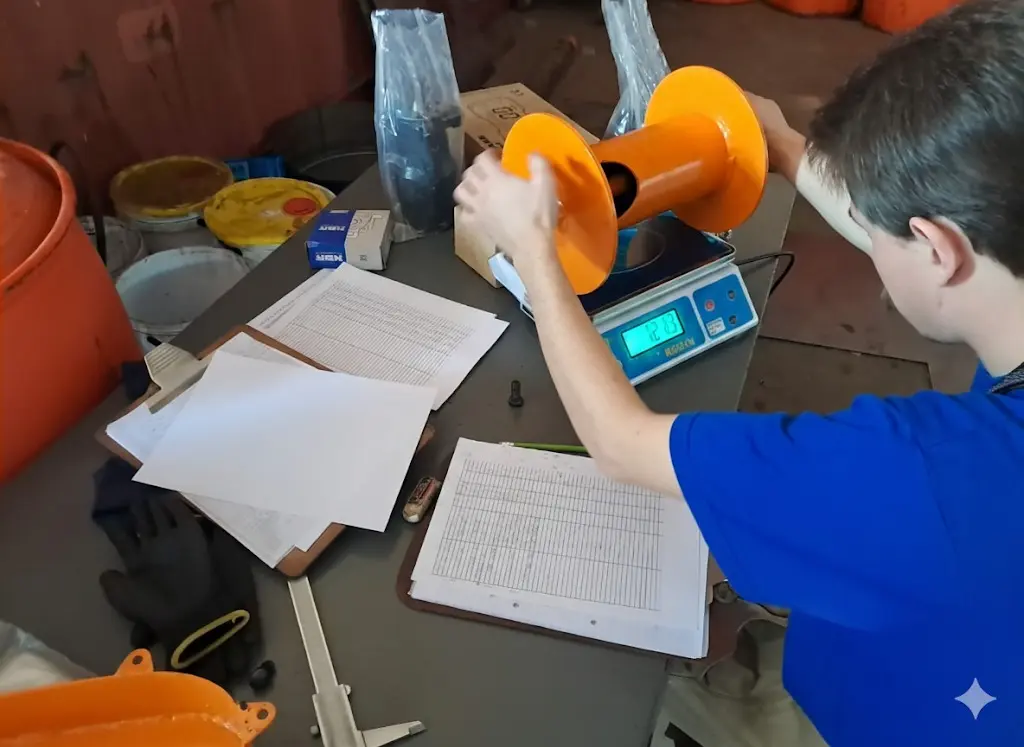

We’re not just disassembling it. We’re cataloging it. Every single part, from the massive mast sections to the smallest hydraulic fitting, is being carefully removed, cleaned, professionally photographed, and precisely weighed.

A Time-Consuming Task with a Clear Purpose

Let's be clear: this is a marathon, not a sprint. It’s a meticulous, time-intensive process that requires a dedicated team of skilled technicians and a whole lot of patience. So, why are we doing it? The answer is simple: to make our products and our service better for you, our customers.

This project is a fundamental investment in knowledge. When it's complete, we will have a comprehensive, granular database of our equipment that is second to none. This isn't just about having a parts list; it's about having a complete blueprint for excellence.

How This Unprecedented Detail Benefits You

- Unmatched Accuracy in Service: When you need a replacement part, you need the right part, fast. With a detailed photograph and exact specifications for every single component, our service team can identify and ship what you need with pinpoint accuracy, minimizing your downtime.

- Smarter Logistics and Planning: Knowing the precise weight of every single part revolutionizes logistics. It allows for more accurate transport quotes, safer load planning, and more efficient on-site maintenance. When you know exactly what a component weighs, you can plan your crane lifts and site movements with confidence and safety.

- Driving Future Innovation: For our engineers, this project is a goldmine. Having a complete rig deconstructed allows them to analyze every design choice, every weld, and every bracket. It’s a unique opportunity to identify areas for improvement, whether it’s reducing weight without compromising strength, enhancing durability, or making parts easier to service in the field.

Building a Better Rig, One Bolt at a Time

We believe that leadership in our industry means going the extra mile. It means investing time and resources into projects that don't just build machines, but build confidence, reliability, and a better customer experience.

This deep dive into the anatomy of our rigs is a testament to that commitment. It’s a long road, but we know that by understanding our equipment down to the last bolt, we are building a stronger foundation for the future—for us, and for you.